With the improvement of the living standards of the people, more and more attention is paid to food safety and quality. Pretty much people will wonder why some frozen foods will deteriorate within their shelf life. Will the frozen dumplings sold in supermarkets be deformed? Even why some people are put at risk after eating frozen dumplings? To break down your confusion, an important means to know the quality and safety of fresh products is through cold chain logistics. Based on the analysis of the concept of cold chain logistics, this article analyzes the necessity of preventing cold chain break in cold chain logistics and listed smart beacon applications for maintaining fresh cold chain logistics.

An introduction to cold chain logistics

The rapid development of the logistics industry requires the continuous improvement of cold chain logistics, which plays a huge role in the storage, transportation, and distribution of fresh foods. In fact, the preservation of agricultural products relies heavily on the freezing technology of cold chain logistics, and the fresh products delivered to consumers are not only ensured by the freezing technology of cold chain logistics but also by cold chain break prevention technologies throughout the whole transportation process.

From the production of upstream products to the sales of downstream commodities, fresh products must be preserved in a low-temperature environment. Only in this way can a certain degree of freshness of the foods be guaranteed, and the loss of product freshness reaching the hands of consumers can be minimized as much as possible. Therefore, in cold chain logistics activities, the low-temperature distribution system is bonded to advanced technology and complexity, and at present, such a system is crucial for consumers and will make great contributions to the progress of the current cold chain logistics industry.

An introduction to cold chain break

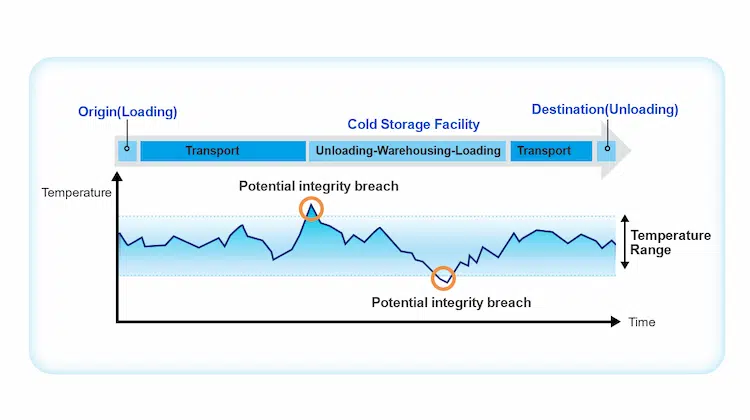

Cold chain break refers to the consequences that due to the low utilization rate of cold chain logistics equipment or improper and wrong operations of enterprises and staff, fresh products are put in an unsuitable temperature that is beyond the recommended safe range, such as normal temperature or high temperature. Food safety problems caused by cold chain breaches can greatly affect the life quality and health of people.

Despite an increasing demand for cold chain solutions, millions of dollars are wasted from cold chain break every year. In order to prevent cold chain break from the point of origin through the distribution chain to the final consumer, smart heat-sensitive devices are adopted to monitor and sense the temperature variations of foods at each point within the chill chain. That’s what we are going to talk about today – smart beacons are identifying and preventing cold chain breaks.

Why cold chain break monitoring important

Freezing maintains the storage life of food by making it more inert, limiting or slowing down harmful reactions that promote food spoilage. However, it should be recognized that many physical and biochemical reactions can still occur, many of which will be more severe when the recommended treatment, production, and storage conditions are not maintained. Cold chain detection technology is suitable for the detection of the validity period of all kinds of fresh products that need refrigeration, which can ensure the safety and effectiveness of fresh products and reduce the rate of decay caused by broken chains.

Temperature-sensitive monitoring technology is therefore to monitor whether the frozen product has heated up above the set temperature, and measure the time experienced by the product above the temperature. It also reports whether the product has a history of thawing during storage and transportation. It is suitable for the monitoring of chilled and quick-frozen foods, especially for products that are preserved fresh by quick-freezing technology. This method is highly complementary to the temperature monitoring of cold chain logistics, which can effectively fill the monitoring blind spot of the latter and avoid the product loading and unloading process or human factors that make the product leave the cold chain for a long time.

What products are affected if cold chain breaches

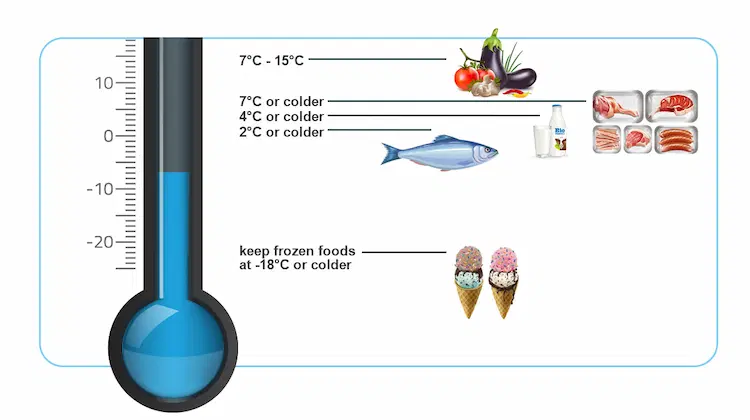

There are diverse mechanisms for governing the quality degradation rate of different foods, so the temperature requirements exist distinctive for each type of food. The most effective way of preventing breaches in the cold chain is to subject the fresh products to long-term storage within the prescribed temperatures. Typically, there are three types of products that are most sensitive to hypothetical cold chain break.

Primary agriculture foods: such as vegetables, fruits, meat, poultry, eggs, aquatic products, and flowers. In order to maintain the safety and quality of these temperature-abused foods, there are specified maximum temperatures. Currently, according to the International Carriage of Perishable Foodstuffs, the maximum temperature of certain foods in transportation is stipulated as follows: 15°C for vegetables and fruits; 7°C for meats; 4°C for poultry, milk and dairy products; 3°C for offal; 2°C for fish.

Processed frozen foods: including meat packaged cooked food, ice cream, dairy products, chocolate, and fast food ingredients. It is recommended to keep stable food temperatures at -18°C or colder, although short-term exceptions of -15°C are allowed during transportation or local distribution.

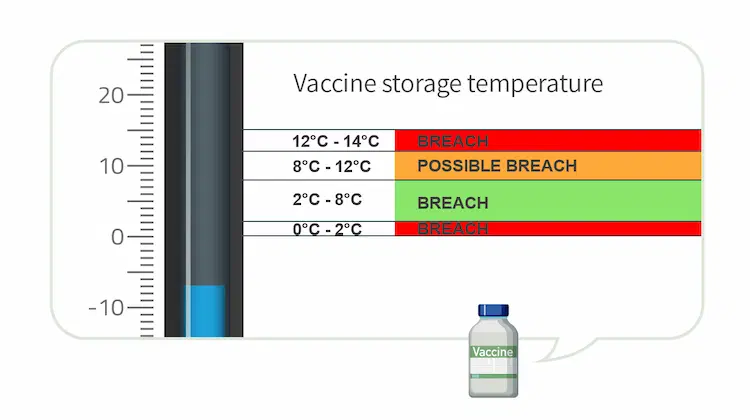

Special goods: such as pharmaceuticals and vaccines. The requirements of such commodities are higher and more complex than normal temperature logistics in a cold chain, and so do the costs. Vaccines can be less effective or even destroyed if they are exposed to temperatures beyond the recommended range of 2°C to 8°C.

What are the possible breaks in the cold chain

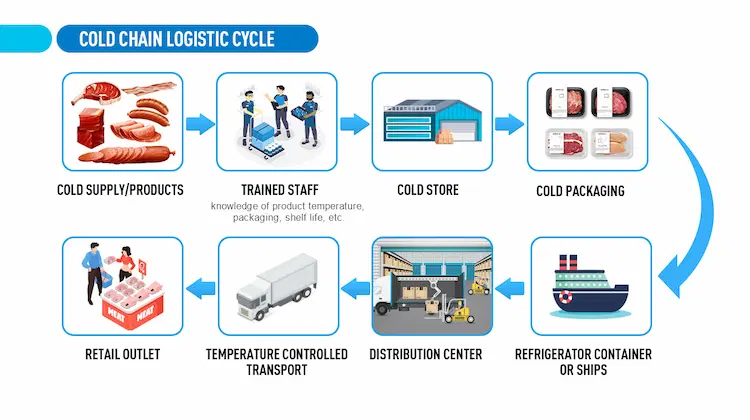

The sequence of events within a typical cold chain is illustrated in the following images, and it’s clear that there are many potential warm links to concerned suppliers, carriers, and retailers. In fact, these links all have something to do with the activities in which the product is ‘touched’ – through multiple storage and transportation stages. Each activity inside the supply cold chain can cause possible degradation of products and increase the probability of discontinuity of the cold chain.

| Cold chain activity | Common cold chain break |

| Production | No timely transfer into the storage; the temperature of the warehouse rose too much |

| Transportation | Unexpected shutdown of refrigeration equipment during transportation |

| Loading and unloading | There is no special low-temperature loading and unloading area; no standard palletizing measures |

| Storage | Excessive fluctuations of temperatures in the warehouse |

| Distribution and retail | No insulation measures for cold chain foods; excessive fluctuations of temperatures in the display cabinet |

Beacon applications in preventing cold chain break

In order to maintain a high quality of chilled and frozen foods, the prevention of cold chain breaches is of great significance for each stage of the operation. Monitoring the cold chain includes real-time location tracking, accurate food product temperatures, and more. Smart Bluetooth beacons play a key role in monitoring locations and measuring temperatures.

With the help of MokoBlue smart beacons, you are not only accessible to the real-time location of the perishable and frozen foods but also can you detect abnormal temperature fluctuations and take instant measures to prevent breaks in the cold chain, thus supporting continuous delivery from the food producer to the consumer.

Production and Storage: keeping ideal temperature range

In the processing and packaging of chilled and frozen products, a certain ideal temperature range should be ensured in the packaging and storage room. Problems may emerge as early as the production and packaging process, as well as the condition from warehouses that have not been sufficiently pre-cooled before collection. If this happens, it may have an influence on the safety, quality, and shelf life of the product. The MOKOBlue Temperature&Humidity sensor beacons are well-designed to measure and monitor temperature changes, and they will trigger alarms as soon as the temperature is outside the prescribed temperature range.

Loading and unloading: locating the products as quickly as possible

There are no special low-temperature tally rooms in some cold stores, and the products are exposed directly to the outside air when loading and unloading, which is unfavorable to ensuring the temperature of the cold chain products, especially in the hot summer. Therefore, carrying out loading and unloading tasks as quickly as possible can prevent long-term exposure of food and medicines to ambient temperatures. MOKOBlue location beacon supports real-time location tracking of cold chain products in order that a faster loading and unloading task could be achieved within large warehouses and factories.

Transportation: matching temperature to product

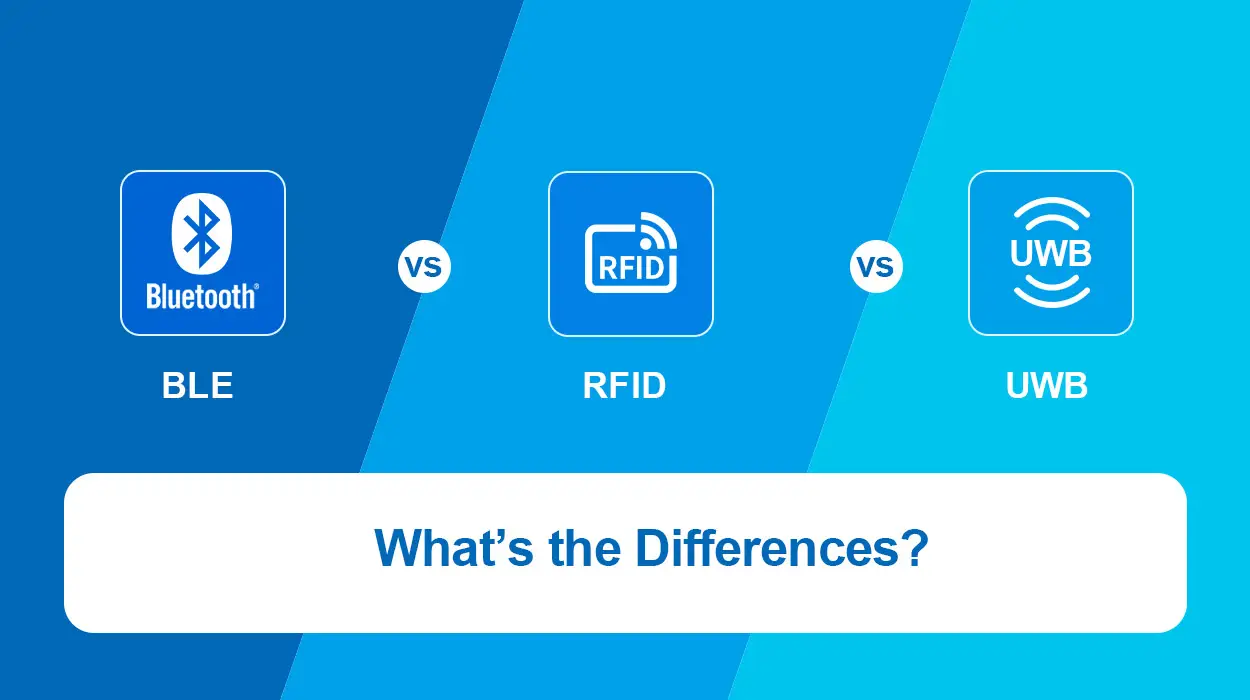

Transportation takes an important part of the entire cold chain, so ensuring an acceptable temperature range in transportation activities assumes considerable importance. Pretty much refrigerating and freezing vehicles adopt positioning management systems to deal with the quality problem in the circulation of foods, and advanced technologies such as RFID, GPS, and temperature sensing technology are also integrated into the prevention. There is no doubt that smart Bluetooth temperature beacons are a necessary part of maintaining an ideal preservation temperature.

Learn MOKOBlue cold chain monitoring solutions

Now that you’ve learned a little about cold chain break, you can talk to an expert of MOKOBlue to learn more about smart temperature&humidity sensor beacon monitoring and real-time location solutions. To help you monitor and measure temperature in the cold chain, MOKOBlue offers various Bluetooth beacons and gateways.